Researcher: Chao-Hui Feng

My research interests lie on the frontier of meat science and food technology and are targeted on the development of food technology to exploit new foodstuffs and improve the food quality and rapid detect the food safety. Time saving and convenient ready-to-eat food products are becoming increasingly popular due to the rise in “money rich, time poor” individuals. The increasing availability of processed foods is enabling this trend. Sausage casings, a natural permeable membrane (like a “skin”) used for producing sausage, should be strong enough: 1) to resist pressures during batter filling and stuffing; and 2) to hold the batter during the heating and smoking processes. As natural casings are variable in caliber and elongation capacity, casings can easily burst during stuffing and it hinders the efficiency of sausage production. Therefore, there is highly demand for improving the property of the casings and the natural hog casing was modified for the first time by surfactant solution and slush salt with lactic acid. As one of my previous research studies, the effects of soy lecithin concentrations, soy oil concentrations, residence time for surfactant solutions and lactic acid concentrations on technological properties of hog casings were evaluated by response surface methodology.

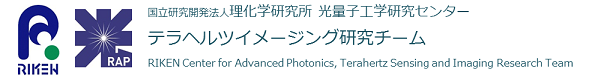

Figure 1 (a & b) illustrated the interactive relationship between soy oil concentration and lactic acid concentration. Rupture force of uncooked casing achieved a higher value (> 60 N) when a casing was submitted to a lower soy oil concentration (< 2.0%) with a higher lactic acid slush salt concentration (>20 ml/kg NaCl). A lower lactic acid concentration combined with a long residence time tended to have a low rupture force value for cooked casing, which can be observed in the above Figure 1 (d).

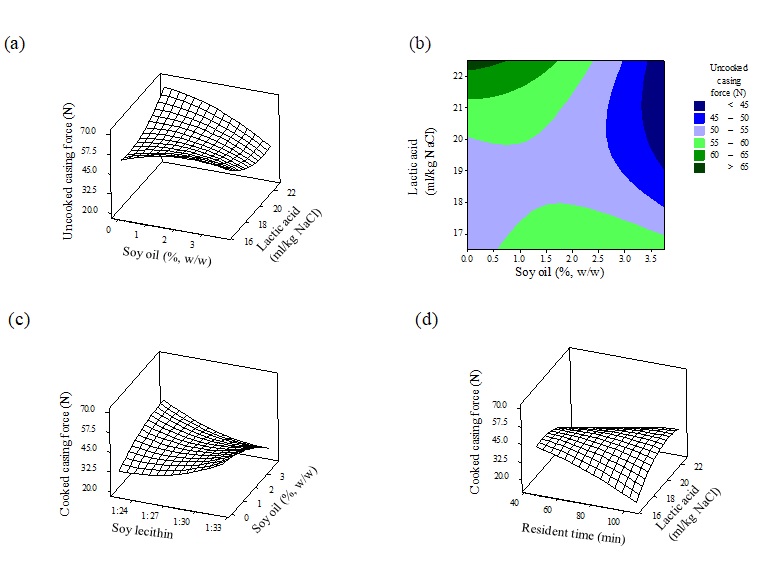

Subsequently, transmission electron microscope (TEM) was used to observe the interior structure of casing before and after casing modification.

Figure 2 elaborates images (um = μm) obtained by TEM (120 kV) for cross sections of sausages. (a) stuffed in raw hog casing with magnification level of 1700× and (c) 2250×; (b) modified casing and then cooled by IVC with magnification level of 1700× and (d) 2250×. Fat globule can be identified in Figure. 2 (d), where the structure of the untreated casing was “compressed” after immersion vacuum cooling. It can be easily found that the casing became more porous after modification.

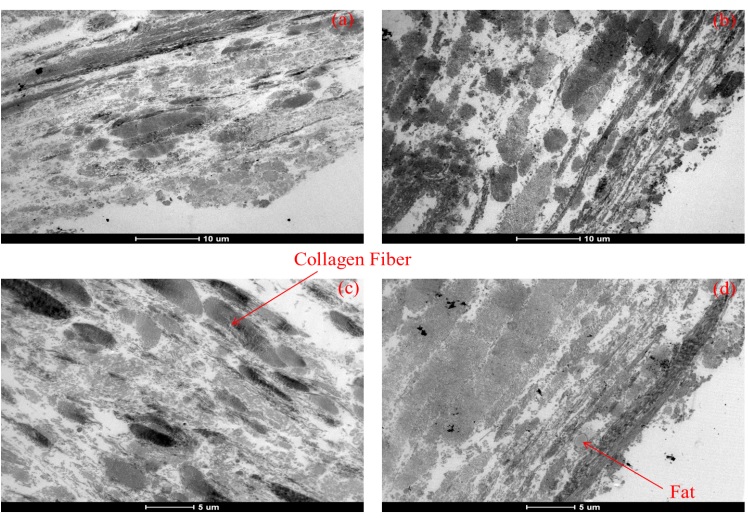

During the postdoctoral research in the University of Tokyo, my topic was focused on non-invasively evaluating meat quality by using hyperspectral imaging. Figure 3 displays the visualisation of redness distribution map for sausages store at 8 oC for 0 d (a, d), 16 d (b, e), and 57 d (c, f). Based on the naked eyes, the samples with different storage days were difficult to be identified from the RGB images [Fig. 5 (a-d, m-o)]. However, how much and where the different redness values were located from spot to spot in different test samples will be elaborated in the distribution map [Figure 3 (d, e, f)].

My future research topic will be focused on to broaden the application field of terahertz spectroscopy to new foodstuffs.